Why Choose a Dual Channel Syringe Pump?

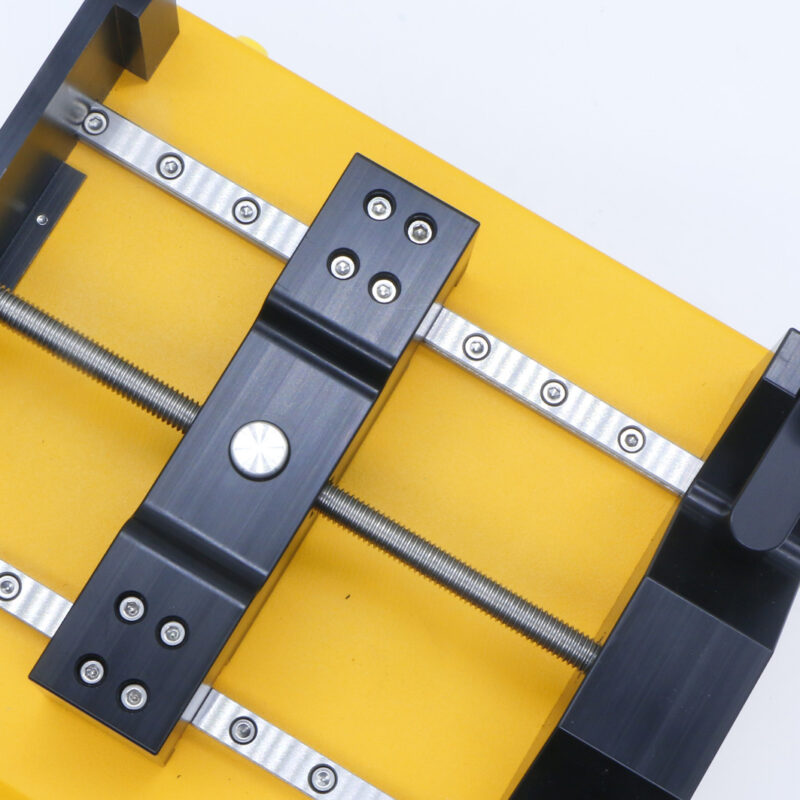

A dual channel syringe pump like the IPS-13 offers clear benefits over single-channel systems. With two syringes driven by a single synchronized motor, both plungers move together to deliver matched, simultaneous flow. The flow ratio between channels is set by syringe diameters (or downstream resistance), enabling gradient mixing, co-axial electrospinning, and parallel fluid delivery. This coordinated operation saves time, improves accuracy, and expands experimental options.

Applications of a Dual Channel Syringe Pump

The IPS-13 dual channel syringe pump is ideal for advanced lab and industrial tasks. It delivers stable flow in microfluidics, enables co-axial fiber production in electrospinning, and supports perfusion, gradient mixing, and precise dispensing. With wide syringe compatibility and programmable operation, it ensures reliable performance across diverse research fields.

For more details on electrospinning and nanofiber research, visit the Inovenso website.